Primary and fine roller mills play a central role in the preparation of ceramic raw materials. Indeed, there is no alternative to roller mills for fine comminution as part of plastic preparation. Many brickmakers work with raw materials for which a roller gap of roughly 0.8 mm or wider achieves adequate comminution. HÄNDLE’s Beta roller mill concept was developed as a cost-effective, state-of-the-art alternative to the Alpha II. Beta fine roller mills are value-for-money machines offering effective roller gaps down to 0.8 mm. Four sizes are available with volumetric throughputs up to approx. 75 m³/h (132 t /h wet) for an 1-mm gap setting and a peripheral velocity of 20 m/s. And when we say “state of the art”, we are talking about things like optimal cost-benefit ratio, gap consistency and convenience of operation.

Daten | Fakten

DATEN | FAKTEN

Daten und Fakten kurz und übersichtlich für Sie zusammengefasst.

Historie

HISTORIE

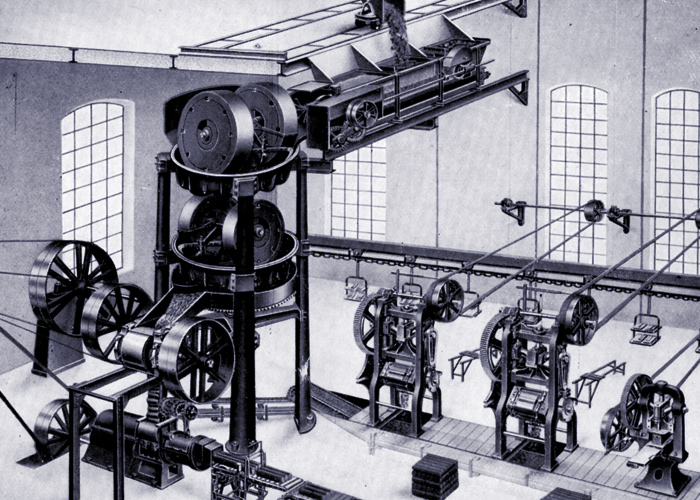

Mundstückbau von KAMPEN: damals und heute

Messetermine

MESSETERMINE

Aktuelle Termine

Presse

PRESSE

Aktuelle Veröffentlichungen