Nowadays, market-appropriate roof-tile collections must include a diversity of standard and accessory tiles. The situation poses a major challenge to any and all producers, because the difficulty of keeping production processes eco-nomical increases with the number of design variants.

The WEGA pressing system optimally meets all such require-ments. Three different versions are available for covering any individual range of application (soft or stiff pressing with any customary type of mold material like plaster, metal or rubber): WEGA S II with 2 synchronous 90°-rotating pressing tables equipped with 1 top-half mold and 2 bottom-half molds for a maximum stroke rate of 8/min = 480 pressings/h WEGA S III with 3 synchronous 120°-rotating pressing tables equipped with 1 top-half mold and 3 bottom-half molds for a maximum stroke rate of 12/min = 720 pressings/h WEGA S IV with 4 synchronous 90°-rotating pressing tables equipped with 1 top-half mold and 4 bottom-half molds for a maximum stroke rate of 13/min = 780 pressings/h The table measures 560 x 754 mm for a maximum mold moun-ting area of 500 – 650 mm. The useful mold-group height is adjustable between 170 mm and 300 mm.

The 300-mm working stroke can accommodate practically any conceivable type of tile. A maximum pressing force of 1500 kN or 2000 kN enables perfect forming / expression, even of complicated models.

Daten | Fakten

DATEN | FAKTEN

Daten und Fakten kurz und übersichtlich für Sie zusammengefasst.

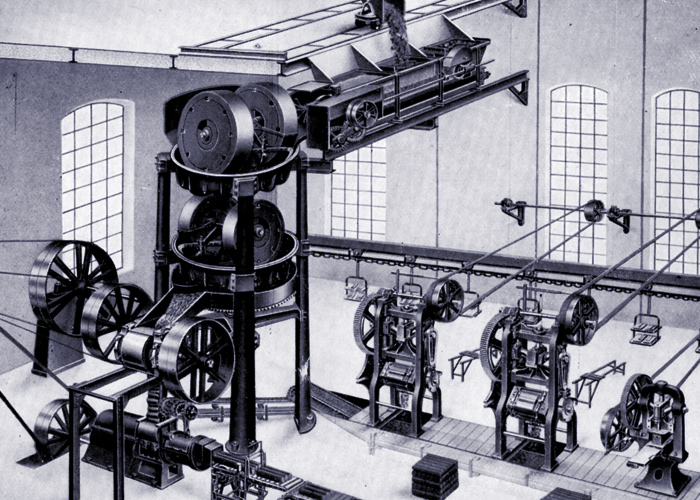

Historie

HISTORIE

Mundstückbau von KAMPEN: damals und heute

Messetermine

MESSETERMINE

Aktuelle Termine

Presse

PRESSE

Aktuelle Veröffentlichungen